For 6000 years we have made objects out of metal because it is strong and resistant: it takes a lot of energy to break it. The problem is that it takes a lot of energy to even repair it. You need a blowtorch that heats the metal parts up to 3500°C. Today, for the first time in the world, a research team has developed a way to repair metal at room temperature. A "regeneration" completely similar to the repair process of our bones, which will lead to the birth of a real metallic bone.

The study was conducted by James Pikul, assistant professor of Mechanical Engineering at the University of Pennsylvania, and Zakaria Hsain, a student of his. The results were published in the Advanced Functional Materials journal.

Research in a nutshell

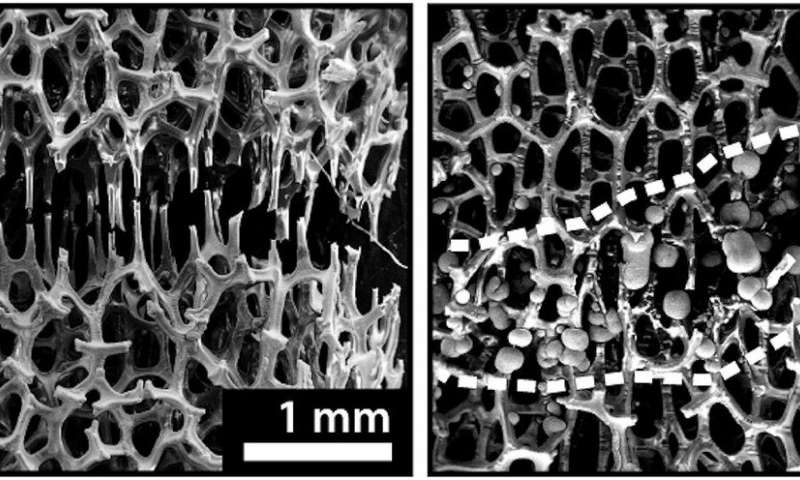

The “porosity” of the internal structure of a metal foam reduces the weight of a metal while maintaining its strength, but makes it impossible to repair it with traditional methods.

If a metal breaks, in fact, bringing it to the melting temperature would destroy the internal cavities of metal foam.

The electrochemical technique used adds metallic material only in the "fractures" of the broken one, almost as if it were a metallic glue, repairing the structure.

Plated and repaired

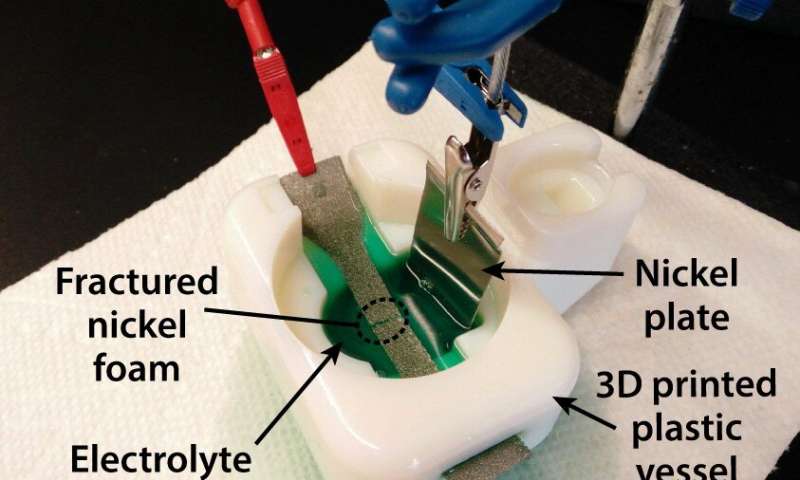

It is the electroplating, a low consumption procedure that takes place at room temperature. It is commonly used for chroming auto parts, or plating metals. By wetting the broken metal in a solution containing chromium ions and applying a voltage, the ions react forming a mass that fills the broken parts of the metal. And that's it.

The results

Pikul and Hsain “healed” three types of damage in as many experiments: metals with cracks inside, metals that were almost broken, metals separated into two parts.

The duration of the procedure is approximately 4 hours, and since plating occurs simultaneously, the time taken does not depend on the size of the metal to be repaired.

“Self-repairing”, like bones

To those who point out that this repair approach is not truly "self-repairing" (because a voltage must be applied to produce the reaction), Pikul says that it is absolutely identical to the repair processes in our body.

“Everyone would say that our bones repair themselves,” says the researcher, “and our material is just like bone. Even the bone requires an external source of energy to repair itself, in that case the food we eat." True.

Metallic bone, therefore

The similarity with our biology will direct the future of this research towards the creation of a metal bone that will constitute the skeleton of each device, small or large. “The electrolyte that produces the repair can be integrated into metal structures in liquid form,” says picul. A bit like a fluid, even blood, which brings nutrients inside an organism.

“In the event of damage, the liquid will surround the damaged area and repair it with a voltage that can be obtained from the internal power supply itself, or from a battery.”

In other words, in the future we will have cell phones, car doors, robot and perhaps space stations that have a skeleton of “metal bones” that repair themselves like ours when they fracture.