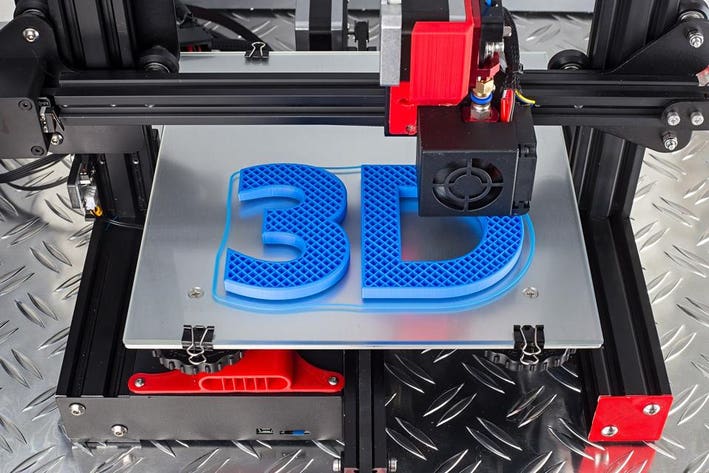

The introduction to the topic of the benefits of 3D printing in the next decade offers an overview of emerging technologies and products in this sector. This advanced form of manufacturing offers a number of benefits, including product customization, adaptability to individual needs, printing speed and accuracy, efficiency and environmental sustainability, in addition to multiple industrial applications. This article will explore in detail all the major aspects and purposes of 3D printing in the next decade.

The benefits of 3D printing in the next decade: an overview

3D printing offers a wide range of benefits over the next decade. Thanks to its ability to customize products and adapt to individual needs, it will become an essential tool for manufacturing industries. 3D printing technology is also improving in speed and accuracy, enabling faster, higher-quality production. Furthermore, 3D printing is highly efficient and sustainable, reducing waste and emissions. With the wide range of industrial applications, 3D printing is expected to have a significant impact in the coming years.

Emerging technologies in 3D printing

3D printing continues to evolve thanks to new emerging technologies. One of these is color 3D printing, which allows you to create complex models with a variety of shades and shades. Another growing technology is metal 3D printing, which enables the production of high-quality, durable metal components. 3D printing with composite materials, such as carbon fiber, is becoming increasingly popular for creating lightweight, durable products. Furthermore, the use of biodegradable materials is gaining ground in 3D printing, allowing for greater environmental sustainability. With these emerging technologies, 3D printing is opening up new design and manufacturing possibilities.

Customization

3D printing technology offers extensive possibilities for product customization. Thanks to this technology, it is possible to create unique objects tailored to individual needs. 3D printing allows you to customize shapes, sizes, colors and materials, offering the possibility of creating truly unique products. This feature makes 3D printing an ideal solution for personal needs and for the creation of commissioned products.

3D printing and product customization

3D printing offers the ability to create customized products for individual needs. Thanks to this technology, it is possible to customize the shapes, sizes, colors and materials of the products, guaranteeing an unprecedented level of customization. This allows consumers to obtain unique and tailor-made objects that perfectly reflect their preferences and needs. 3D printing opens the door to a world of possibilities for product customization.

3D printing and adaptability to individual needs

3D printing offers unique adaptability to individual needs. Thanks to this technology, it is possible to create personalized objects based on each person's specific preferences and requirements. This means that products can be made to measure, with specially chosen shapes, sizes, colors and materials. This flexibility allows consumers to obtain unique products perfectly suited to their needs.

Speed and accuracy

3D printing also offers significant advantages in speed and accuracy. Technological advances in the industry have made it possible to increase the speed of printing, allowing the production of complex objects in much shorter times than traditional production processes. Furthermore, 3D printing can ensure precise precision in the creation of complex and intricate details, allowing the creation of high-quality, precision products without compromising efficiency.

The rapid evolution of 3D printing speed

In recent years, 3D printing speed has made great advances, allowing for faster and more efficient production. New technologies and improvements in printing algorithms have led to shorter print times, allowing complex objects to be created in significantly less time. This has allowed us to reduce production times and meet the needs of a continuously growing market. The speed of 3D printing will continue to evolve over the next decade, opening up new opportunities in manufacturing.

3D printing and precision in complex productions

3D printing offers an unprecedented level of precision in complex manufacturing. Thanks to its ability to create objects with minute details and intricate geometries, 3D printing allows you to create components and prototypes with extreme precision. This translates into greater quality of the final products and the possibility of creating customized pieces that respond exactly to the specific requests. The precision offered by 3D printing opens up new possibilities in industries such as automotive, aerospace and medicine, where precision is key.

Efficiency and sustainability

In the context of industrial production, 3D printing offers important advantages in terms of efficiency and sustainability. Thanks to the possibility of creating parts and components directly from raw materials, 3D printing helps reduce material and energy waste. Furthermore, eliminating the need to produce, transport and store traditional spare parts allows us to reduce the environmental impact linked to the production of waste and greenhouse gas emissions. 3D printing is therefore confirmed as a sustainable and efficient solution for the production needs of the next decade.

Environmental sustainability in 3D printing

3D printing offers a significant advantage in terms of environmental sustainability. Thanks to the ability to use only the amount of material necessary for the production of parts and components, 3D printing allows you to reduce raw material waste. This significantly contributes to minimizing the environmental impact associated with industrial production. Furthermore, 3D printing also reduces greenhouse gas emissions, as it eliminates the need for transportation and storage of traditional spare parts.

Reduction of waste and emissions thanks to 3D printing

3D printing contributes significantly to reducing waste and environmental emissions. Thanks to its ability to create objects with only the amount of material needed, 3D printing reduces raw material waste. Furthermore, because it eliminates the need for transport and storage of traditional spare parts, 3D printing also contributes to the reduction of greenhouse gas emissions. These factors make 3D printing a sustainable and environmentally friendly option for industrial production.

Industrial applications

3D printing has numerous applications in the industrial sector. Thanks to its ability to produce customized spare parts in shorter times and at lower costs than traditional production, 3D printing is revolutionizing the maintenance and repair processes of industrial equipment. Furthermore, adopting 3D printing allows companies to optimize production and reduce overall production costs. These industrial applications offer significant advantages in terms of operational efficiency and product quality.

3D printing in the industrial sector: advantages and opportunities

3D printing has opened up new opportunities in the industrial sector, offering significant benefits to companies. With the ability to produce customized and complex spare parts, 3D printing reduces downtime and production costs. Furthermore, the adoption of this technology allows for high production flexibility and rapid prototyping, allowing companies to develop new products faster and make the most of market opportunities.

3D printing and reduction of production costs

3D printing has revolutionized the manufacturing industry due to its ability to reduce production costs. With this technology, companies can eliminate the need for large quantities of waste materials and reduce costs associated with transportation and warehousing of parts. Additionally, 3D printing allows companies to reduce production times and costs associated with the part assembly process. All this translates into a significant reduction in overall production costs. Online you can find various players in the sector such as FAMA3D which allow you to get an immediate quote.

Conclusions

3D printing represents an ever-evolving technology with multiple benefits over the next decade. Thanks to customization, speed and precision, efficiency and sustainability, and industrial applications, 3D printing promises to revolutionize several sectors. With the continuous development of new technologies and materials, the future of 3D printing looks promising and could have a significant impact on manufacturing and innovation.

Potential future developments in 3D printing

Over the next decade, 3D printing is expected to continue to evolve significantly. Emerging technologies, such as 4D printing and bioprinting, could further expand the potential of 3D printing. Furthermore, the materials used are expected to become increasingly advanced, enabling the production of even more complex and functional objects. The miniaturization and cost reduction of 3D printers could also promote the widespread adoption of this technology across several industries.

Impact of 3D printing in the next decade

The impact of 3D printing over the next decade will be significant and transform many industries. The possibility of creating personalized objects, the greater speed and precision of printing and the reduction of waste and emissions will contribute to the efficiency and sustainability of production. The increasingly widespread application of 3D printing in industry will lead to reduced production costs and new opportunities for innovation.