The energy value of hydrogen is 39,4 kWh per kilogram, but creating it with a current electrolyser costs about 52,5 kWh. An Australian company called hysata claims that his new cell reduces the energy cost to 41,5 kWh and beats efficiency records, while also being cheaper to install and operate.

The company promises green hydrogen at around 1,50 euros per kilogram in a few years. The research is published in the open access journal Nature Communications..

Efficiency: major obstacle for hydrogen

Greater efficiency would allow more energy to be stored and support rapid refueling: in other words, it would make hydrogen competitive and widespread on the market.

If Hysata's new electrolyzer technology delivers on its promise, the efficiency of the electrolysis process will increase significantly, making better use of precious clean energy. This equipment can actually drive down the price of green H2 to the point where it becomes competitive with dirty hydrogen or even fossil fuels.

How does an electrolyser work today?

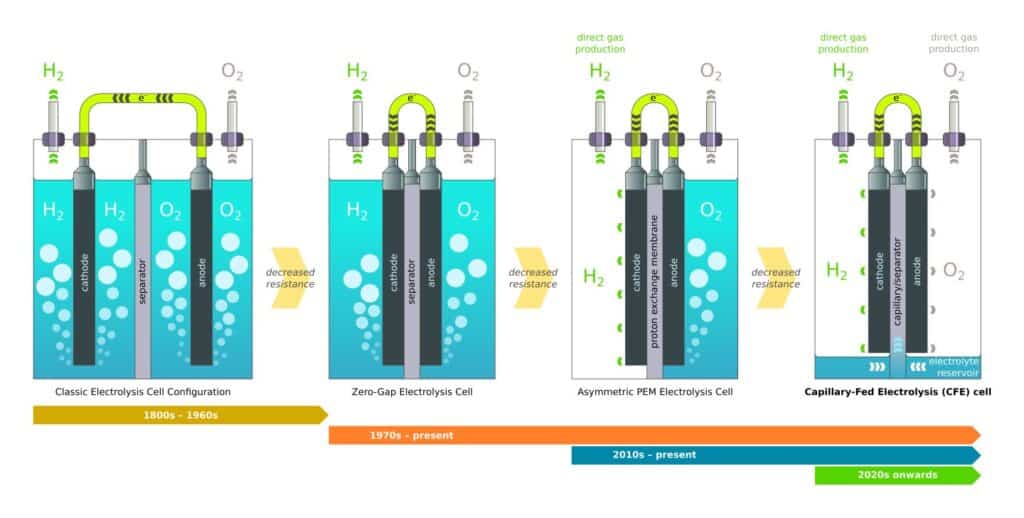

In early versions, the anode and cathode were both immersed in the electrolyte, causing bubbles to form around them. In the 70s, zero-gap electrolysis connected the anode and cathode directly to the separating membrane, achieving higher efficiency (with bubbles only on one side). The polymer electrolyte membrane (PEM) method, first developed in the 70s and early 80s, progressively allowed the cathode side of a battery to operate without an electrolyte. This further increased efficiency by producing hydrogen gas without bubbling it through a liquid. But it's still not enough.

How does the Hysata electrolyser device work?

Hysata's electrolyzer cell takes things to the next, and perhaps final, level. A reservoir at the bottom of the cell keeps the electrolyte out of contact with both the anode and cathode until it is drawn through a porous, hydrophilic, interelectrode separator using capillary action. The electrolyte therefore has direct contact with the electrodes, but only on one side, and both hydrogen and oxygen are produced directly, without bubbles getting in the way.

Resistance is further reduced by no water being drawn from the side of the electrode that is releasing gas, so the two don't get in each other's way, and as the water is electrolysed out of the separator, capillary action draws it higher from the tank to replace it.

The Hysata team claims that its “capillary” electrolyzer has record efficiency of 98%, far superior to that of a "commercial polymer membrane electrolyzer", which reached an efficiency of 83%. The technology also reduces additional costs: there is no need for circulation of liquid, no need for tanks that separate gas and liquid, or pumps, or fittings.

Add all the components, the overall efficiency is 95%. Its energy 'cost' is 41,5 kWh/kg. The average efficiency of any other electrolyzer is 75%.

What can change with this system

For hydrogen producers, an electrolyzer like this could significantly reduce both the capital and operational costs of producing green hydrogen. An epochal transition, like the transition to electric starting from the combustion engine.

The CEO of Hysata Paul Barrett, states that the company will commercialize the technology and “mass-scale hydrogen production capacity by 2025.” Hysata is building a pilot plant to produce the electrolyzer, and will make several hires this year.

A great coup in the context of a real "green gold rush". The competition to bring hydrogen into thegreen economy turns on, and a cheaper and more efficient electrolyser would be in great demand.