You have a real disaster ahead of you: you can no longer count the glass glasses that the undersigned has clumsily disposed of. Maybe from today I will be less afraid of getting into trouble: Penn State, a university in the United States, He developed a type of glass called LionGlass that not only has 10 times the resistance to damage, but also requires much less energy to produce.

Green transparency

The most used glass (we find it in practically everything, from windows to glasses) is sodium silicate and lime glass. To produce it, ovens reaching 1500°C are needed, a process that consumes a lot of energy and releases huge amounts of CO2 into the atmosphere. That's not all: the basic materials for this type of glass are quartz sand, soda ash and limestone: the latter two also release CO2 when they are melted.

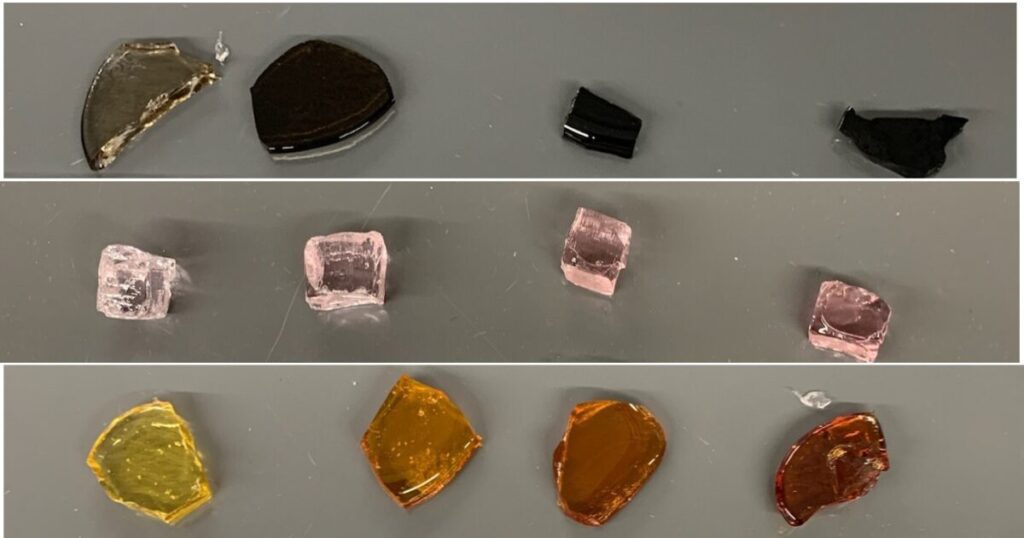

What's now? The team of researchers at Penn State has developed the formula for a stronger and greener glass. This new family of glass, called LionGlass, gets its “superpowers” by replacing soda ash and limestone with aluminum oxide or an iron compound. The silica content can vary from 40% to 90% by weight.

That's not all: replacing the carbonates reduces direct emissions during smelting and lowers the required temperatures up to 400°C. This in turn reduces energy consumption by about 30% and consequently reduces emissions.

And it is also much more resistant

In laboratory tests, LionGlass outperformed traditional glass, proving to be 10 times more resistant: the samples "attacked" with a Vickers diamond indenter did not make a bend (or rather: a crack) even under a load of 1 kg, compared to 100 grams of normal glass. “We continued to increase the weight on the LionGlass until we reached the maximum load that the equipment allows,” he says Nick Clark, a researcher involved in the project. “It just didn't crack.”

The team believes that the benefits of LionGlass could be multiplied in the real world. With much stronger glass, products can be thinner and lighter. “We should be able to reduce the thickness and still get the same level of damage resistance,” he says John Mauro, principal investigator of the project. “And the prospect of making products lighter will be huge for the environment: less energy to produce and fewer raw materials used.”

Possible applications

This development in glass could have a huge impact on many industries, from construction to the automotive industry.

In constructionFor example, it could enable the creation of much stronger and more durable windows and glazing, reducing the risk of damage and the need for frequent replacement. In the automotive industry, LionGlass could be used for windshields, making them safer and more impact resistant. In fact, it could even find application in space tourism. In the field of electronics, mobile devices such as smartphones and tablets could benefit from stronger and more durable screens. Finally, at home, producing dinnerware from LionGlass could lead to virtually indestructible glassware and plates. ME-proof, so to speak.

The team filed a patent application for LionGlass last year, and hopes to bring it to market soon. I can't wait, and neither can my wife: I ruined the old 12 service and she's worried about the new one.

Hurry up!