Houses made with a new high-tech wood will help reduce emissions by lowering the costs of home air conditioning.

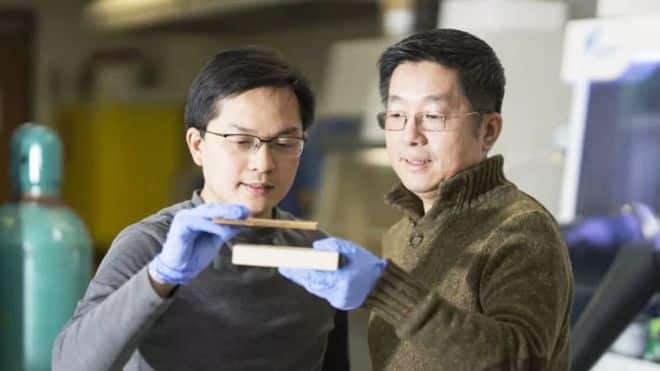

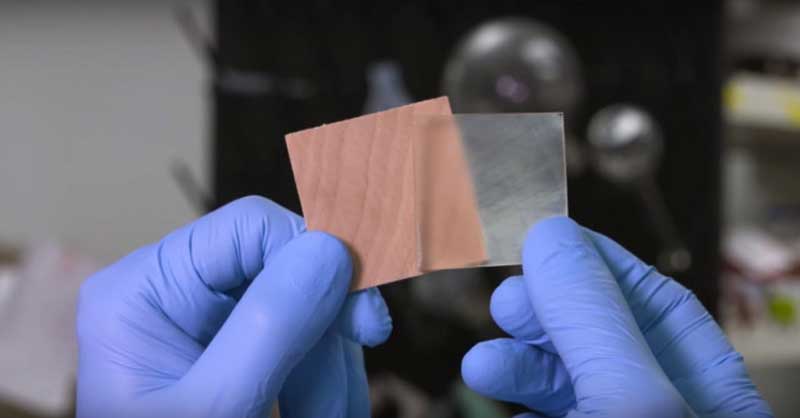

Liangbing hu and his colleagues at the University of Maryland created super wood by removing lignin from natural wood (an organic polymer found in the plant cell wall) with the help of hydrogen peroxide (trivially: hydrogen peroxide).

What remains is a material made largely from the other component of the cell wall: cellulose, which reflects visible light and absorbs very little infrared. In fact it is a "cooling" wood.

The research team verified an important ability of super wood: that of absorbing the heat inside the house during the day (which has a different wavelength than the sun's) and releasing it outside during the night.

The quality characteristics

The researchers report that the new wood is very dense and has a strength of about 404 megapascals, making it nearly 9 times stronger than natural wood and comparable to metals such as steel.

To measure the amount of energy it can absorb, the team "replaced" walls and ceilings of apartments in 16 American states, evaluating the response of the super wood depending on the climate: on average, the reduction in air conditioning costs is from 20 to 35%.

Given its characteristic, Hu explains, the material is ideal for areas that are warm and sunny for a long time, like Arizona and Hawaii.