Rechargeable lithium-ion batteries have become an important power source for electronic devices and electric vehicles, aiming for a greener future. However, their production involves costs to the environment and human health that must be addressed and reduced. Despite the availability of crucial battery materials such as Lithium, nickel, cobalt e graphite is not in discussion, their cost is increasing. Both in economic and environmental terms.

The extraction of these materials involves a high consumption of energy and water. To facilitate a transition that is not a "bloodbath", we must essentially do two things: transform all extraction processes in a sustainable way, and recycle the valuable components of the batteries: until yesterday, both things presented many complexities.

And tomorrow?

Scientists of the Berkeley Lab in California they have created a material that can solve the problems related to the extraction of raw materials for reuse. In practice, it can make it easier, cheaper, cleaner and more sustainable to recycle batteries. The material, called Quick Release Binder, is a binder composed of two cheap and available polymers, polyacrylic acid (PAA) e polyethyleneimine (PEI) joined together by a bond between nitrogen and oxygen atoms. This new binder dissolves easily in a room temperature alkaline water solution containing sodium hydroxide.

To recycle batteries made with this material, simply open their casing, immerse them in an alkaline water solution and shake them gently. This process allows the sodium ion to separate the two polymers, which dissolve in the liquid and release any components embedded within the electrode. The separated components can be easily removed from the water and left to air dry.

Recycling batteries: what about today?

As mentioned, the current lithium-ion battery recycling process is complex and consumes a lot of energy, as well as waste. It requires shredding and grinding batteries, followed by burning them to separate the metals from the components.

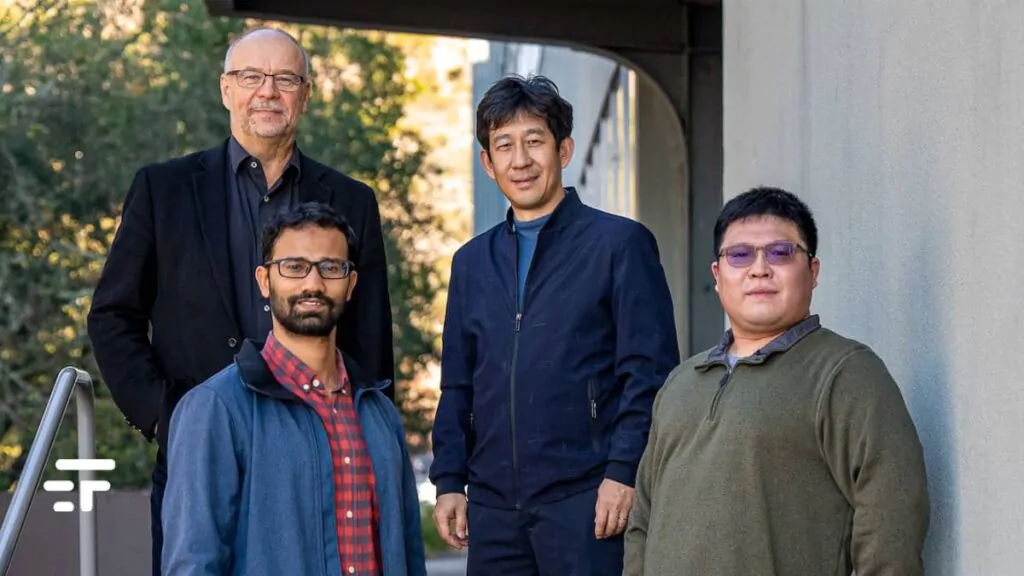

The newly developed method seems significantly more advanced and sustainable for the environment. I would add: the new “quick release” binder is free of harmful chemicals and the production and decomposition processes do not require the use of aggressive solvents. The research team is working with Steve Sloopfounder of OnTo Technologies and battery recycling expert, to complete product testing and market launch.

The target? License this Quick-Release technology, so that all manufacturers eager to sell easy-to-recycle batteries come forward.