In the United States, heart disease is the leading cause of death for the population. They are responsible, you think, of at least 47% of deaths also in Europe. According to the data collected USA, every 36 seconds a person dies from cardiovascular diseases. Why have we not yet managed to mitigate this worrying fact?

There are many reasons, but one most of all is interesting for the purpose of this article: heart tissue does not regenerate. Other organs and tissues in our body can regenerate after an injury, but our heart cannot. This is why tissue bioengineering, which also includes the fabrication of an entire biohybridized and transplantable human heart, is so important for the future of cardiac medicine.

A "natural artificial" heart

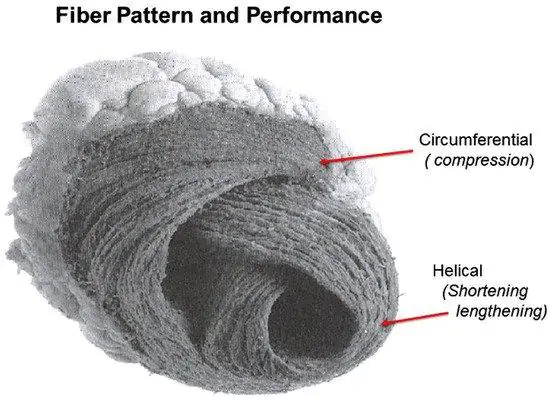

In recent days, the bioengineers of Harvard's John A. Paulson School of Engineering and Applied Sciences (SEAS) developed the first biohybrid model of a human ventricle with helically aligned beating heart cells and demonstrated that the alignment of the muscle cells, in fact, dramatically increases the amount of blood the ventricle can pump with each contraction.

How did they make the biohybrid model of the human heart?

This progress was made possible thanks to a new method of additive textile manufacturing, the Focused Rotary Jet Spinning (FRJS). The method enabled the high productivity fabrication of helically aligned fibers with diameters ranging from a few micrometers to hundreds of nanometers.

Developed at SEAS by Professor's Disease Biophysics Group Parker kit, FRJS fibers direct cell alignment. And they allow the formation of precisely organized structures, which simulates the arrangement in a natural human heart.

The creation process

The first phase of the FRJS works a bit like a cotton candy machine. A liquid polymer solution is loaded into a tank and pushed out through a small opening by centrifugal force as the device spins.

When the solution leaves the tank, the solvent evaporates and the polymers solidify into fibers. Then, a focused airflow controls the orientation of the fibers as they are deposited onto a collector.

The team found that by angling and rotating the collector, the fibers in the flow align and twist around the collector itself as it rotates, mimicking the helical structure of the heart muscles.

Biohybrid heart: perspectives

The team also showed that the process can be scaled to the size of an actual human heart and even larger, to the size of a whale's heart (they didn't fill the larger models with cells, because it would take billions of cardiomyocyte cells).

This study is as interesting as regards the medical perspectives (and therefore the possibility of recreating a biohybrid heart functioning in the laboratory), as for the possible implications of FRJS technology in other areas. In addition to tissue biofabrication, the team is also exploring other applications for the FRJS system, such as food packaging.

In conclusion, we recommend watching a short video regarding what has been read so far, published by the Harvard School of Engineering and Applied Sciences. Finally, we also refer you to the article posted on their site.