A team from MIT and Rhode Island School of Design has developed an acoustic fabric that works like a microphone, converting sound into mechanical vibrations before transmitting them into electrical signals, just like our ears.

All tissues vibrate in response to sound, although these vibrations are on the nanoscale and therefore too minute to be perceived. To capture these subtle signals, the researchers developed a flexible fiber that bends with the fabric like algae does on the ocean surface when it becomes entangled with it.

The material converts sound waves into electrical signals through a “piezoelectric” process: it can capture sounds of intensity between the silent library and city traffic, and determine their direction. The acoustic fabric also has the ability to detect the characteristics of the wearer's heartbeat, and in turn generate sounds.

Possible applications

The study detailing the device was published on Nature. The main author Wei Yan sees many uses for acoustic fabric.

You can converse with an acoustic garment to answer calls and interact with others. Furthermore, heart and respiratory problems can be monitored in real time, continuously and in the long term, with this tissue.

Researchers predict that a directional sound-sensing fabric could help people with hearing loss tune into a speaker in a noisy environment. Acoustic fabric could be incorporated into maternity clothing to help monitor a baby's fetal heartbeat.

Furthermore, it could even be integrated into buildings to “listen” for cracks and deformations. The borders are very vast.

Sound layering

Fabric has long been used to dampen or muffle sound: think of the carpet in our homes, or panels to soundproof rooms. The MIT team has been working for years to add functions to fabrics by improving the characteristics of the materials. In this case they were inspired by an incredible instrument: the human ear.

In the ear, sound waves from the outside world are converted into vibrations and electrical signals. When these waves reach our ear, in an exquisitely sensitive and complex three-dimensional organ called eardrum, are translated into mechanical vibrations by a circular layer of fibers. The vibrations are then picked up by small bones and transported to the inner ear, where the cochlea transforms the waves into electrical signals which are recognized and interpreted by the brain.

The team wanted to build an “ear” that was soft, durable, comfortable and capable of detecting sound. His study revealed that such an acoustic fabric would need stiff or “high modulus” fibers to effectively convert sound waves into vibrations.

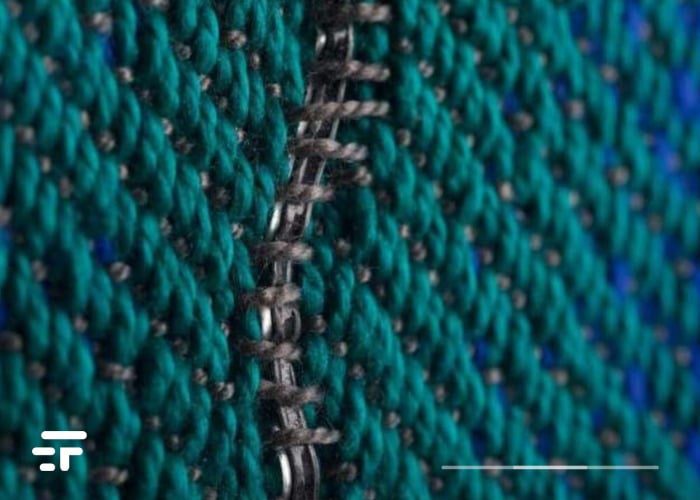

Following these guidelines, the team built a first block of material composed of a piezoelectric layer and other elements that increase vibrations in response to sound waves. The block, the size of a thick marker, was then heated and "frayed" into thin and very long fibers (about 40 meters). A new smart fabric.

Good listening

Scientists tested the sonic sensitivity of the fiber by attaching it to a sheet of mylar hanging from the ceiling. They used a laser to evaluate the vibration of the sheet and, consequently, the fiber in response to sounds made by a nearby speaker.

The performance of the fiber on the membrane was comparable to that of a handheld microphone.

Next, the team woven the fiber with conventional yarns to produce drapable, machine washable fabric panels.

“It almost feels like a light jacket, lighter than denim, but heavier than a dress shirt,” says the co-author Elizabeth Meiklejohn, who spun the acoustic fabric using a standard loom.

This study offers a whole new approach for textiles to listen to our bodies and the world around us.