Soft robotics often intersects with biomimetics, and together they "give birth" to ideas that will enter our future. The researchers of Johannes Kepler University in Austria they have developed a new “gel” for 3D printing robots that can be recycled at the end of their life cycle.

These are “soft robots,” which are typically built from soft materials. As mentioned, one of the most profitable fields of soft robotics is that which aims to create robotic animals, often amphibious or capable of swimming underwater.

Biodegradable robots

The "aquatic" use of soft robotics implies that the materials with which soft robots are built cannot degrade when immersed in water. On the other hand, it is also a problem if these robots end up increasing the environmental impact: how can we solve the problem?

Yes, right. With biodegradable robots.

In the study just published in the journal Science Robotics, the researchers bring known but terrible data: technological waste can accumulate up to the rate of 100.000 tons per day, a rate destined to increase.

Soft Robotics, Sweet Robotics

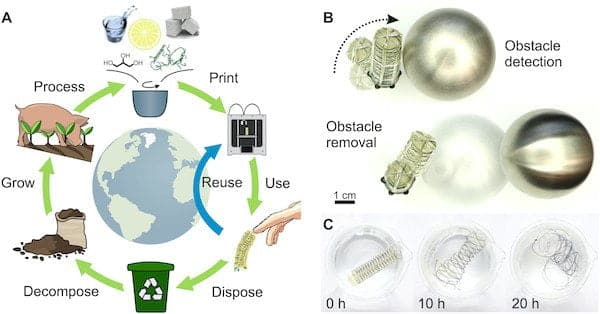

In this new research, the team shows the use of sugar and gelatin (two rather accessible materials) to create a sort of "ink" which, properly heated to the melting point, can be used for 3D printing. Placing the printer in a refrigerated room will allow the material to solidify quickly, maintaining its printed shape.

To test this system, the researchers printed a finger-like form with the new ink. The most classic of soft robots, which uses compressed air to control its movements.

The technique allows for the rapid and low-cost development of prototype robust and soft gel robotic applications that extend six times their original length, but above all a process to easily recycle them.

Five times

This application of soft robotics is a true paradigm of sustainability. Sugar biogel can be reused by printing it up to five times, meaning damaged or outdated robots can be heated to recover the material.

And after these five times?