Safe and readily available water is important for public health, whether for drinking, domestic use, producing food or recreational purposes.

Despite the large amount of water on the planet, only 2,5% is fresh water: it is estimated that 785 million people do not have a clean source of water to drink. Seawater desalination could be a vital technology for meeting the world's drinking water needs.

Now, a team of Korean engineers has developed a new desalination technique that takes just minutes to make seawater drinkable.

How the system for desalination of sea water works

The team used a new nanofiber membrane distillation process that can desalinate seawater with an efficiency of 99,99%.

Commercialization of this technology could help humanity cope with drinking water shortages in the future.

The problems just solved

Among the most challenging problems in membrane distillation is the fact that this membrane gets wet: this makes it lose effectiveness in a short time.

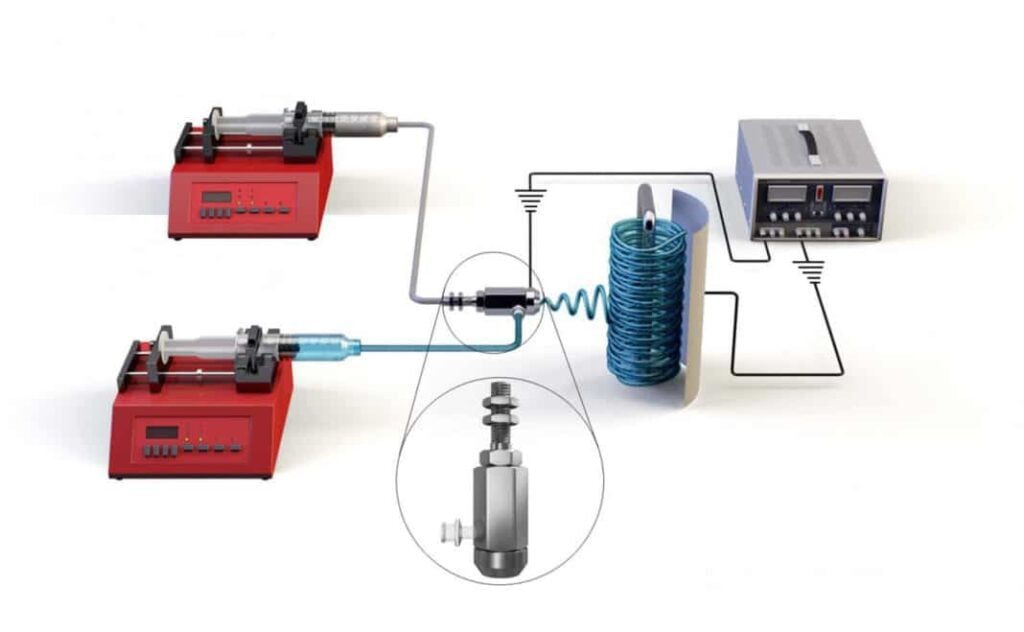

The engineers ofKorean Institute of Civil Engineering and Building Technology (KICT) have developed special nanofiber membranes. The special feature is the use of an alternative nanotechnology called electrospinning, which prevents problems and improves the long-term stability of the membrane.

Electrospinning is the key to rapid desalination of seawater

Coaxial electrospinning technique is one of the most favorable and simple options for fabricating effective membranes for making seawater drinkable.

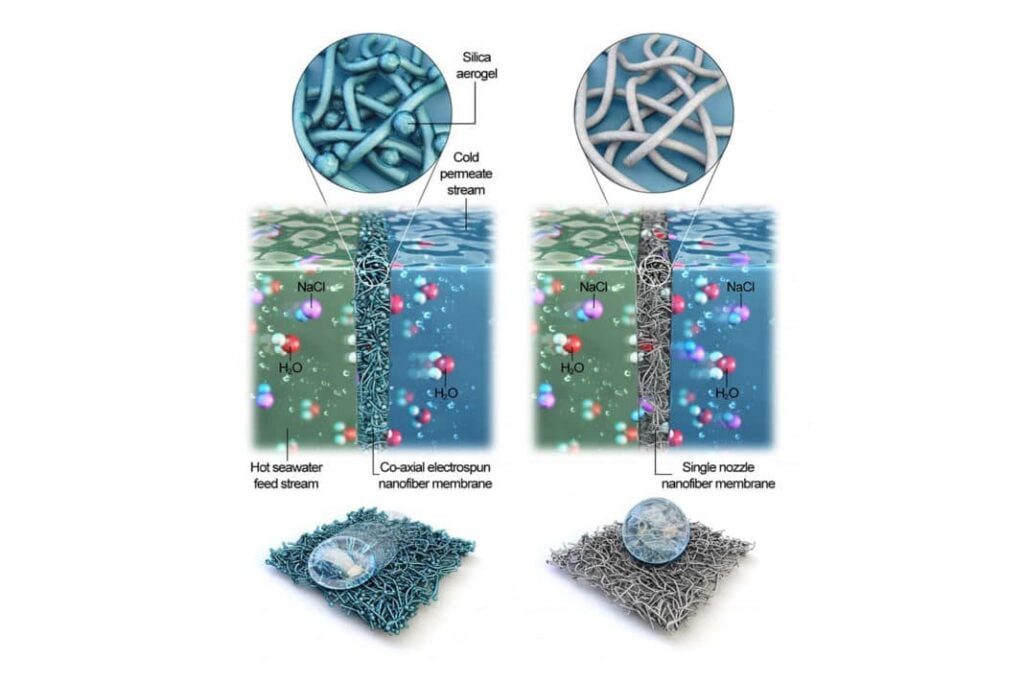

In scientific terms, the engineers used a core (vinylidene fluoride-co-hexafluoropropylene) and a sheath (silica airgel). Result? A composite membrane with a superhydrophobic surface.

It resists wetness, yields more, does not overheat and is more effective. Much more effective.

Laboratory tests

During testing, the team was able to maintain stable membrane distillation for 30 days. During those 30 days, the electrospinning nanofiber membrane maintained a 99,99% seawater salt rejection rate.

This is a much longer run time than other electrospun nanofiber membranes in previous studies that ran for less than 50 hours with high water vapor flow.

“The coaxial electrospun nanofiber membrane has strong potential for treating seawater solutions. It is the most serious candidate for large-scale use,” he says Yunchul Woo, lead researcher of the study.

Currently, the main method of seawater desalination is reverse osmosis. An approach adopted in approximately 20.000 specialized factories around the world.

Unfortunately, reverse osmosis uses a huge amount of energy and this process of desalination of seawater, generating harmful waste, is usually discharged back into the sea or ocean.