prvok, tiny house with a view, will be the first 3D printed house in the Czech Republic and will float on a barge, while also being able to stay on the ground.

It is an innovative construction for several reasons. First of all, the tiny house is completed in just 48 hours, it can cost up to 50% of conventional buildings and with 20% less emissions.

Its creator Michal trpak began putting the concept into production with 3D printing this month. He hopes the project will “change the construction industry forever,” making custom homes and buildings more affordable than traditional methods and even other similar buildings.

From four wheels to four walls

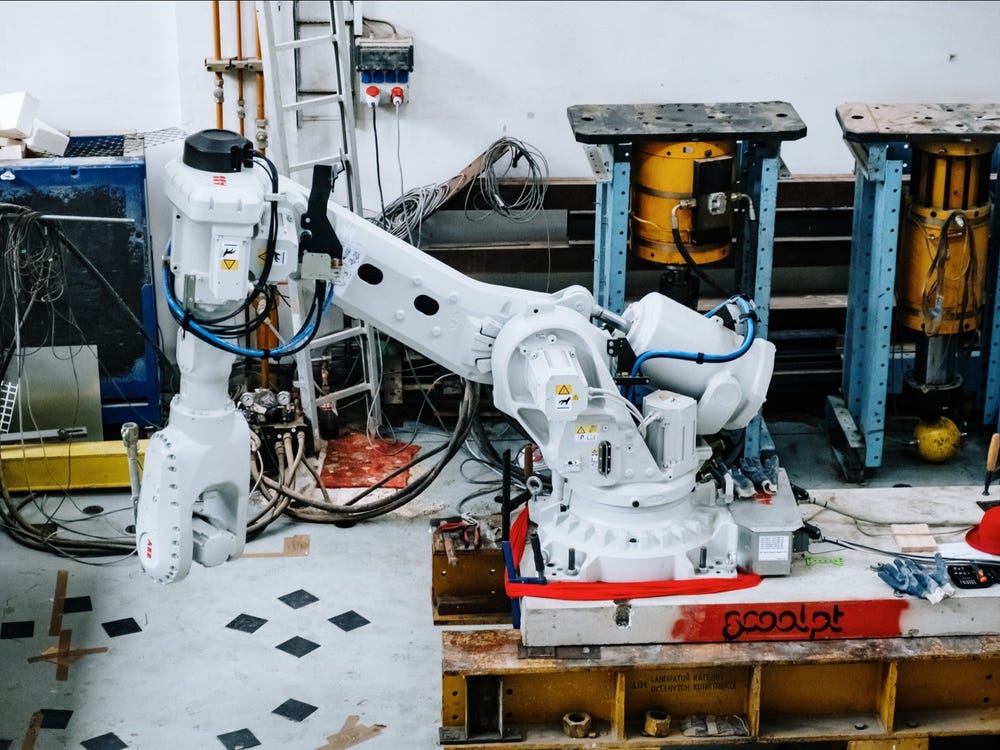

The keystone of the Prvok project is the application of a method designed for other industrial sectors. The tiny house is in fact made with Scoolpt, a robotic arm usually used for automotive production.

This intuition has made it possible to obtain a method seven times faster than the usual ones. 15 square centimeters per second, to create a 140 square meter building in just 48 hours.

Even in terms of production agility, needless to say, the system speeds things up a lot: from 65 construction workers, Prvok can obtain the same building using only 25.

New materials

The tiny house also uses innovative concrete, capable of forming stable volumes more easily. Once printed, the building is left to "dry", reaching optimal solidity within 28 days.

The process also winks at reuse. In the future, owners will be able to destroy the building once its useful life has expired and print it again with the same material right on site.

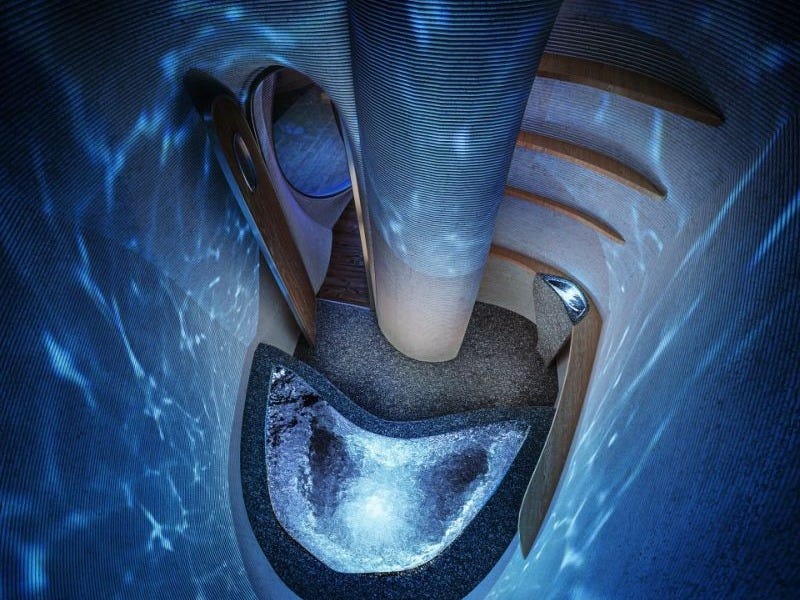

How is it made inside Prvok 3D?

The space and the construction mechanism do not affect the habitability and pleasantness of the internal spaces. The 3D printed tiny house will have three rooms: a bedroom, a living room with a kitchen and a bathroom. Even inside, Prvok is equipped with green technology, such as a recirculating shower and drinking water tanks, which make it partially self-sufficient.