Ultra-precise 3D printing technology is a key factor in the production of precision biomedical and photonic devices. However, existing printing technology is limited by its low efficiency and high costs.

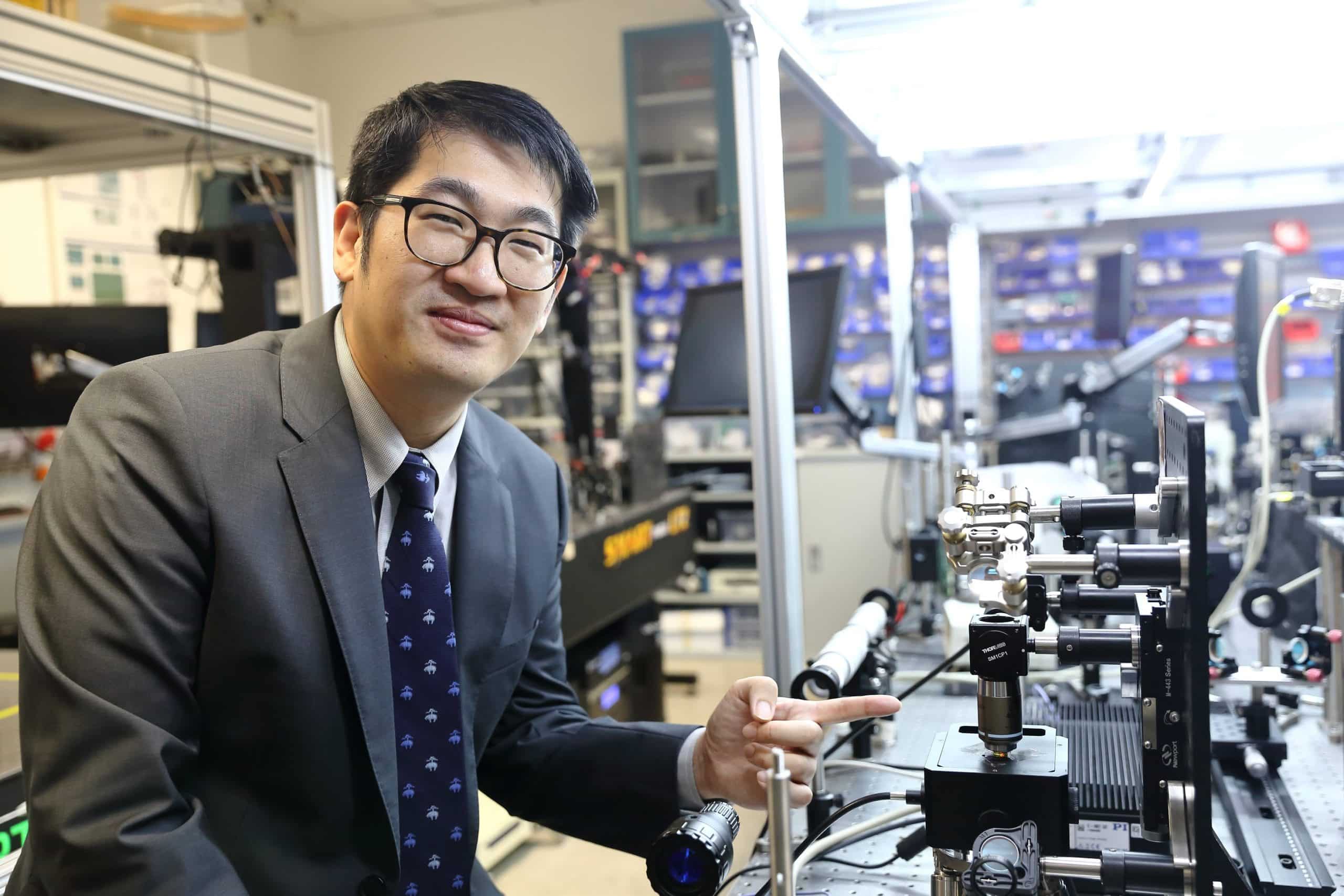

Professor Shih-Chi Chen and his team from the Department of Mechanical and Automation Engineering, The Chinese University of Hong Kong (CUHK), have developed rapid 3D printing technology. The secret is a process called femtosecond projection two-photon halithography (FP-TPL).

By controlling the laser spectrum through time focus, the 3D printing process is performed parallel layer by layer rather than point-to-point writing.

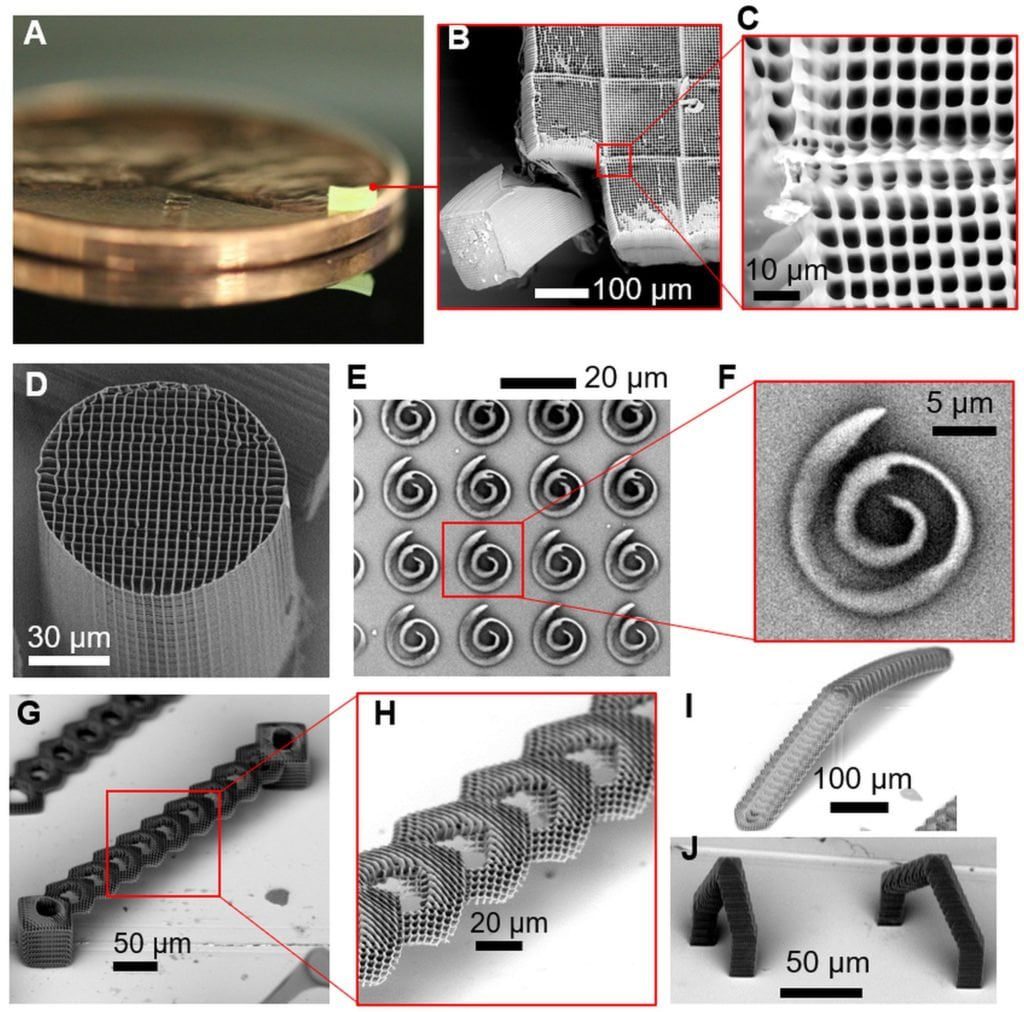

This new technique substantially increases the printing speed 1.000-10.000 times while reducing costs by 98%. The result was recently published in Science, confirming the technological breakthrough that brings nanoscale 3D printing into a new era.

Conventional nanoscale 3D printing technology, i.e. two-photon polymerization (TPP), operates in a point-by-point scan mode. Therefore, even an object the size of a centimeter can take a few days or weeks (construction speed ~ 0,1 mm3 / hour).

The process takes time and money, which prevents practical and industrial applications.

To increase speed, the resolution of the finished product is often sacrificed. Professor Chen and his team overcame the difficult problem by exploiting the concept of temporal focus in which a programmable femtosecond “sheet of light” is formed across the entire plane. It is as if millions of laser points were simultaneously projected onto the plane. In other words, FP-TPL technology can manufacture an entire layer within the time the point scanning system produces a single point.

Fast as lightning, indeed: like millions of lightnings

FP-TPL technology has gone beyond the limits of old 3D printing techniques thanks to its high speed. The partially cured parts are quickly joined together before they can move into the liquid resin, which allows for the manufacture of complex and protruding structures on a large scale.

Professor Chen said that FP-TPL technology can be useful in many areas. For example nanotechnology, advanced functional materials, micro-robotics, medical devices and drug delivery.

Thanks to its considerably increased speed and reduced costs, FP-TPL technology has the potential to be commercialized and widely adopted in the future. Especially if it will be possible to manufacture medium-large sized devices.