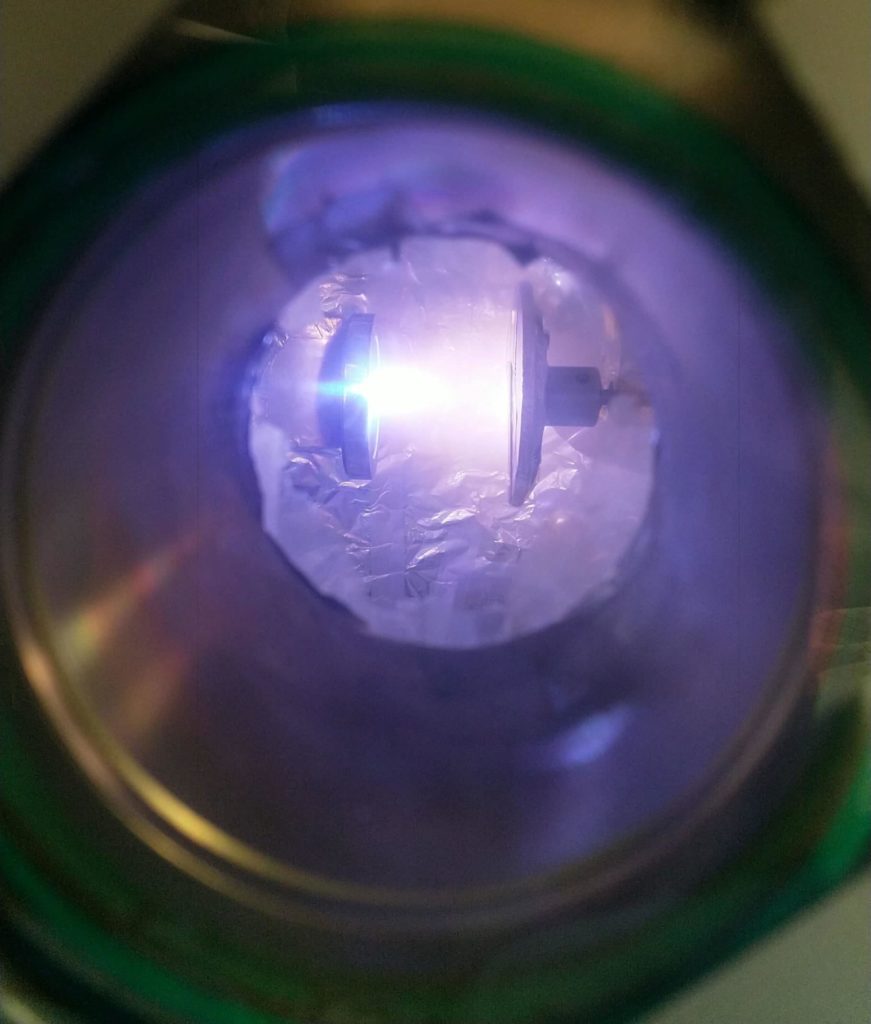

Dr. Erkka Frankberg and co-authors from Finland, France, Austria, Norway, USA and Italy (there is also "our" Matteo Vanazzi from the Polytechnic of Milan) used a technique called pulsed laser deposition to convert thealumina (Al 2 O 3 ) in a state similar to glass.

“Conventional glass is fragile and easily shatters under pressure,” he said Frankberg about the newly developed “transparent metal”. “We have discovered a way to produce glass that exhibits ductile behavior. In other words, our glass is bendable and harder than conventional glass. “

The method adopted

It is extremely difficult to convert aluminum oxide into a glassy substance

Traditional glass manufacturing processes cannot be applied to aluminum oxide because it easily transforms into the crystalline form. The solution is to cool the material extremely quickly from a high temperature to prevent crystallization. What we get is a translucent ductile metal.

Making ductile glass that exhibits plasticity is extremely challenging. For this the process must be further refined and developed before the new type of glass can be produced on a large scale almost like a transparent metal and diffused like others. super materials under study today.

“Both aluminum and oxygen are abundant on Earth, but we need an unconventional production process to achieve the desired properties”, has explained Frankberg.

The ductile glass produced must also be pure and flawless

A high quality glass material is mandatory if you want to make it collapsible. The presence of any imperfections in the glass such as cracks, bubbles or impurities, can cause fractures. “In our glass, the atoms are able to move from one position to another before the glass reaches the stress needed to fracture, while in conventional glass the fracture stress is reached before the atoms start to move, which is why where glass breaks easily,” says Frankberg.

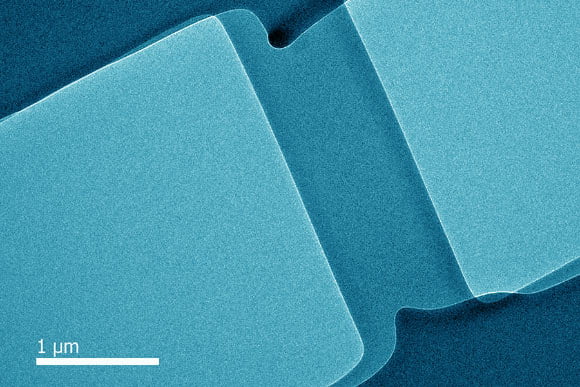

The team prepared thin films of this glass and subjected them to mechanical stress. The material showed properties of a “transparent metal”, was stretched and compressed, as well as sheared.

In the future we will have glass that deforms, gets "dented" but does not break.

“Demonstrating malleability is just the beginning. We will then look at what other types of glass have the same capacity.”

Il work of the team was published in the November 15, 2019 issue of the magazine Science .