It is one of the first combinations between 3D printing and self-healing materials: the future will be full of it.

A research team has announced the development of a whole series of 3D printable materials that can repair themselves, even after a clean cut: the rules of the game could change for fashion, electronics and a thousand other fields.

Professor Qiming Wang and his students from the University of Southern California began by exploiting a manufacturing method called photopolymerization, which uses light to solidify a liquid resin.

To obtain the result, they made endless attempts on timing and dosages to obtain self-repairing qualities without compromising printability.

“By gradually increasing the oxidizing agents, the self-healing behavior improved, but the photopolymerization capacity worsened,” says Wang. “It's a very precarious balance.”

A world that takes care of itself

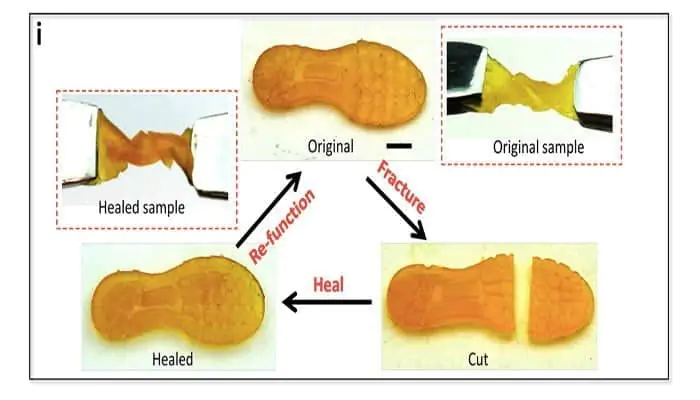

The team tested its method by printing a considerable number of objects: the insole of a shoe, a soft robot, a sensor, then cutting them in half.

After two hours at 60 ° most of these objects have completely repaired themselves (for the sensors it takes longer because of the electronic components).

The “healing” time is further reduced by increasing the temperature.

“In a temperature range from 40 to 60 degrees,” comments the first author of the research Kunhao Yu, “and at different times the materials repair themselves 100%. The process also takes place at room temperature."

Let's get straight to the point: what is missing from the development of spare parts for cars and self-repairing work clothes.

Here is the research published in Nature.