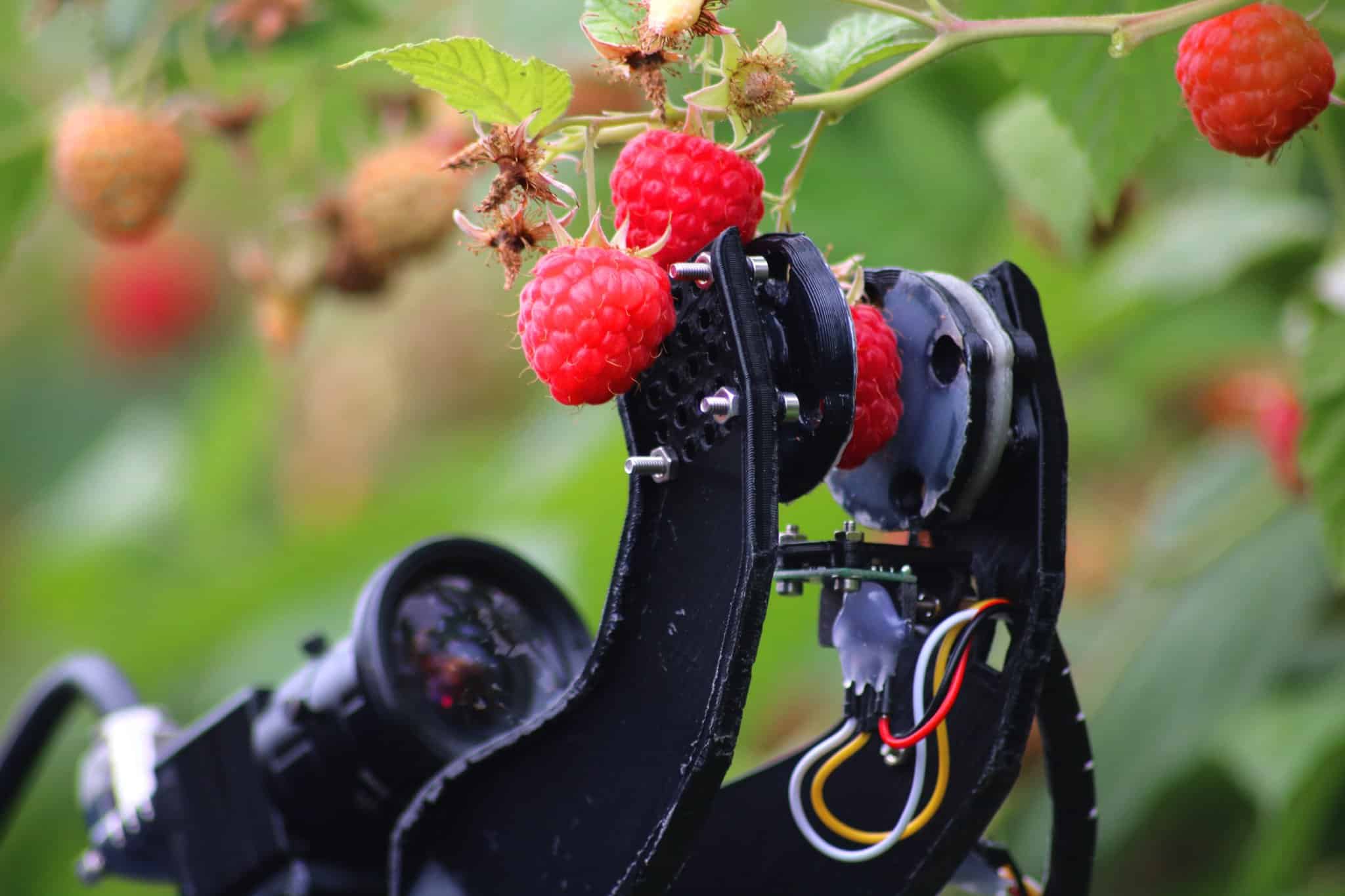

He is still a little unsure like a novice child: he picks a raspberry from the plant, slowly carries it to a basket and lets it go. It takes him a minute to delay, quite a long time for a machine that cost almost 1 million euros to develop, but Robocrop will be the future in fruit harvesting.

According to Fieldwork Robotics, a company founded at the University of Plymouth, each robot will be capable of picking more than 25.000 blackberries a day (compared to the 15.000 collected by one man in 8 exhausting hours of work). The number of seasonal workers is starting to run low, and even the "imported" resources from Romania and Poland now tend to stay at home rather than expatriate: for this reason, robotic alternatives will not be long in coming.

1m, robotic arm and wheels, the metal dude started his tests on a farm in West Sussex and a location in China (there he focuses on tomatoes and cauliflower): guided by sensors and 3D cameras, Robocrop uses a form of AI to perfect its grip on individual fruits simply by analyzing its shape (it takes about 10 seconds to evaluate it).

The final version of the machine, in production from 2020, will be equipped with four arms.

It goes without saying: a robot doesn't get tired, it works at least 20 hours a day and currently the only obstacle is keeping the performance of the cameras intact day and night. Farmers pay between €1.5 and €4 per kilo of blackberries picked by human workers: Fieldwork can rent its robots for less.

It's bittersweet news for the UK: on the one hand, yet another confirmation that human work will be increasingly reduced by robotization. On the other hand, the awareness that technology can also make up for the lack of human resources, and this is the specific case: English agriculture requires 70.000 seasonal workers a year, and is currently understaffed by 6000 units.

England will not be the only one to suffer from these shortages: with the population increasingly concentrated in urban areas it will be increasingly difficult to recruit seasonal workers for rural areas.

The use of robots is also being studied for sowing, milking and ploughing, and everything suggests that this is the long-term trend for agriculture and livestock farming.

La Small Robot Company, a Salisbury company, is testing three different oddly shaped spider-shaped robots equipped with wheels that can plant, water and monitor wheat fields with more efficiency, less water consumption and fewer pesticides.

In the next 10 years we will see a switch between two different types of work: the manual and more widespread one will drop drastically, while the need for technical workers specialized in the maintenance of these machines will emerge.